Innovative Solutions for Cannabis Cultivation: A Sustainable and Cost-Effective Approach

The True Costs of Labor in the Cannabis Industry

The labor costs associated with trellising flower canopies in the cannabis industry play a significant role in the financial landscape of businesses. Let’s examine some real-world examples and statistics to understand the impact on cultivators’ budgets.

Subheading: Real-World Examples of Labor Costs in Cannabis Trellising

According to industry reports, labor costs account for a substantial portion of the expenses incurred in the installation, maintenance, and removal of plastic netting used for trellising flower canopies. These costs vary based on factors such as location, labor market, and the size of the cultivation operation.

For instance, in a large-scale cannabis cultivation facility in California, labor expenses associated with trellising were estimated to be around $5,000 per month. This figure included the wages of skilled laborers responsible for the installation and maintenance of plastic netting, as well as the eventual removal and disposal of the nets. Over a year, this amounts to $60,000, which significantly impacts the cultivator’s budget.

Similarly, a medium-sized cannabis cultivation operation in Colorado reported labor costs of approximately $3,500 per month for trellising flower canopies. This amounted to $42,000 per year. These costs encompassed the wages of laborers, training, and the time and effort required to ensure proper installation and maintenance of the plastic netting.

These real-world examples highlight the financial strain that labor costs associated with plastic netting can exert on cannabis businesses. As cultivators aim to optimize their operations and maximize profitability, exploring alternative methods that are more sustainable and cost-effective becomes imperative.

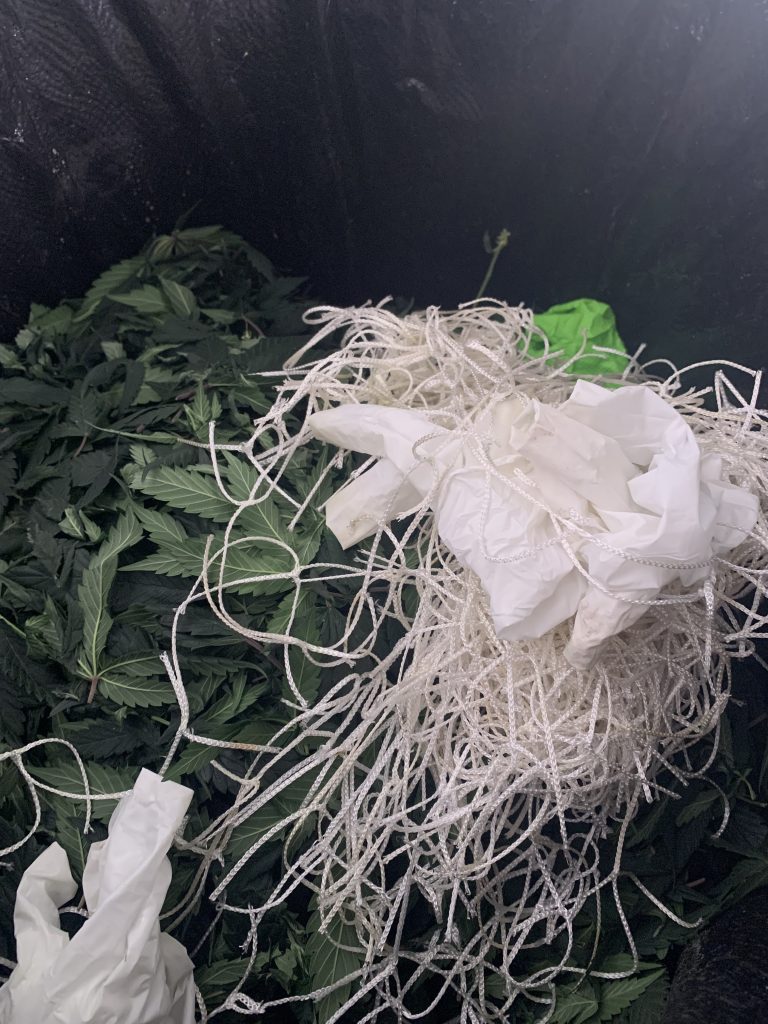

The Environmental Impact of Plastic Netting and Wastefulness

The use of nylon or plastic netting in cannabis cultivation not only has financial implications but also poses significant environmental challenges. Let’s explore how wasteful this practice is and the detrimental effects it can have on the environment.

Plastic netting, typically made from non-biodegradable materials, contributes to the growing plastic waste problem. If not properly disposed of or recycled, these nets end up in landfills, where they take hundreds of years to decompose fully. The accumulation of plastic waste harms the environment, contributes to pollution, and poses risks to wildlife and ecosystems.

Moreover, the production of nylon or plastic netting requires the extraction and consumption of non-renewable resources, contributing to carbon emissions and exacerbating the environmental footprint of cannabis cultivation.

By transitioning to sustainable alternatives like the “Green Tree Scrog” system, cannabis cultivators can minimize their environmental impact and reduce wastefulness. These alternatives, such as reusable frames made from recyclable materials, offer an eco-friendly approach to trellising flower canopies. Not only does this reduce the generation of plastic waste, but it also eliminates the need for frequent replacements, further reducing the strain on the environment.

Conclusion: Embracing Sustainability for a Profitable Future

In conclusion, the costs associated with labor in the cannabis industry related to trellising flower canopies can be substantial and significantly impact a cultivator’s budget. Real-world examples illustrate the financial burden that plastic netting can place on businesses. Furthermore, the wastefulness of plastic netting and its detrimental effects on the environment make it crucial for cultivators to explore sustainable and cost-effective alternatives.

Transitioning to innovative methods like the “Green Tree Scrog” system not only reduces labor costs but also addresses environmental concerns. By adopting reusable systems made from sustainable materials, cultivators can minimize plastic and associated waste.